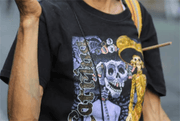

You are thinking of starting a custom t-shirt shop with heat transfer vinyl. Or maybe you're already in the sign and graphics business and are interested in using T-shirt vinyl to expand into apparel decoration. In either case, you may be wondering how T-shirt vinyl crafting works and what it takes to start decorating garments.

For simplicity, this article will deal with easy-to-cut T-shirt transfers, also known as "T-shirt Vinyl" or "heat press vinyl". There are also digital printing options, including printable vinyl, sublimation and other decorations. But for simplicity, this article will focus on heat transfer vinyl that can be used with vector software and vinyl cutters.

We have different types of T-shirt transfer materials to choose from. We now have over 30 different cuttable heat transfer films in hundreds of different colors and patterns. To simplify the selection, we have divided them into the following categories: Heat Transfer Vinyl, Adhesive Vinyl, Printable Vinyl, and Transfer Tape.

Below is a detailed introduction to our Heat Transfer Vinyl: Heat Transfer Vinyl is divided into PET + film + hot-melt adhesive bottom; Heat Transfer Vinyl bottom is hot-melt adhesive, which needs to be heated and dissolved, so as to produce stickiness and adhere to the surface of the item; Heat Transfer Vinyl is divided into PU, TPU and PVC according to the material. PU Heat Transfer Vinyl is used more often. Compared with PVC Heat Transfer Vinyl, PU material is an environmentally friendly material, which is more heat-resistant, softer, and not easy to fall off.

Different Types of Heat Transfer Vinyl

At present, different types of heat transfer vinyl can be found in our website. Including htv vinyl rolls and htv vinyl sheets. Countless styles in both types of colors. Mainly divided into ordinary models and special models.

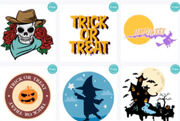

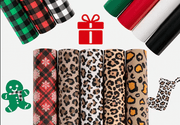

Glitter HTV Vinyl: So far, we've only talked about standard spot color graphics on garments. These are great for the most common applications like softball jerseys. But if you shop around in any department store, you'll find there's a huge demand for more eye-catching clothing. Some call it "Bling". We call it a business opportunity. There are many heat transfer materials that have extra punches. Use these to add metallic and neon colors, glitter, patterns or holographic effects to your custom garments.

Of all the sparkling thermal transfer films on the market, the Ultra Metallic Glitter Film seems to be the most appealing. For this market, we have it. Contains a lot of metal flakes, so they are harder to cut and weed than standard T-shirt vinyl.

Holographic Heat Transfer Vinyl: Holographic heat transfer vinyl creates a multi-dimensional effect and is available in a variety of colors and finishes. While thicker than traditional heat transfer vinyl, it's unique in that it cuts effortlessly to a very rhinestone-like look! Holographic heat transfer will add a whole new dimension to any material and take your designs to a whole new level.

Galaxy Heat Transfer Vinyl: We have a wide selection of pattern heat transfer vinyl that include Space, Galaxy, Aliens and more!

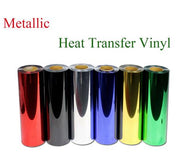

Metallic Vinyl: Bring brilliance to any craft project! Make all your designs reflective and dazzling with Metallic HTV. Metallic Vinyl is easy to weed and can be applied to many textile materials in seconds. Choose from our huge range of colors and don't be afraid to go a little crazy with the colors.

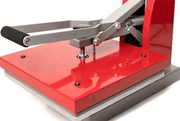

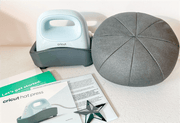

In addition to the vinyl cutting plotter, PC and software, you will also need a heat press for t shirts. We have two t shirt heat presses to choose from. If your production goals are not high, you can start with a small cheap heat press like the mini easy press. If you plan to break into the T-shirt market like the Allies in Normandy, you'll need something stronger. For more detailed advice on how to choose the right heat press, see our post The Ultimate Guide of Heat Press machine.

In addition to hardware and a range of standard and professional heat transfer films, you'll need a few other supplies. Have a pen and paper ready. get ready? OK, you'll need a T-Shirt Alignment Tool, a Teflon Sheet, and some Vinyl Weeding Tools. These devices can save you a lot of frustration. OK! Now go out and make some cool shirts!

How to Use Heat Transfer Vinyl?

1. Design the desired pattern in the software; (Note the mirror image)

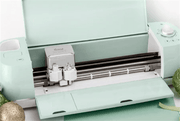

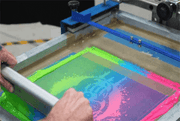

2. Use the cutting plotter to select the appropriate parameters for cutting;

3. Weed the cut material and keep the desired pattern;

4. Iron the clothes flat first, then fit the hot melt adhesive surface of the material to the clothes, cover with high temperature cloth, and wait for the machine to reach the appropriate temperature for ironing;

5. Tear off after waiting for the PET to cool down;

6. It is recommended to wash with water after an interval of 24 hours to avoid the glue not completely melting.

Creating and applying lettering on a T-shirt or sweatshirt is almost the same process as making vinyl graphics. However, before sending a design job in vector software to a vinyl cutter, the file must be reversed so that it is a mirror image of the original design. Think of it like upside-down vinyl for shirts. When you load media on the plotter, the backing paper is facing up. When you draw the film, you are cutting the bottom of the mask, not the top. So you have to flip your design before sending it to the plotter.

Most T-shirt transfers have only one liner, but some have an extra liner (usually pink) to protect the film during shipping. With these products, you must cut off part of the excess lining before starting the drawing or cutting work.

When it comes to cutting, you might see something called a "Cutting Blade." Most heat transfer films are very thin, so you don't need special blades or a lot of force. Can be cut with a standard 45° blade with a force of approximately 75 grams. For thicker vinyl, you will likely need a 60° blade to cut.

Cover the vinyl for shirts with a teflon sheet to provide even heat distribution and prevent anything from sticking to the platen. Set the press to the recommended material time, temperature and pressure, then turn off. After you have finished laminating, wait the recommended time and remove the liner.

Each heat transfer vinyl has its own recommended time, temperature and pressure settings. You can refer to our article Cricut Heat Press Guide for Beginners. Our blog is a treasure trove of helpful tips for beginners to get the information you need.

Application Scenario of HTV

Since these products are designed to be worn, consideration must be given to whether a particular film is suitable for the intended fabric. It doesn't sound complicated. With few exceptions, standard PU and PVC T-shirt vinyls are compatible with cotton, polyester, cotton and polyester blends, and acrylic fabrics. Fortunately, this covers most sales of casual and active apparel. However, these vinyl for shirts are not suitable for all garments. Time and temperature requirements may damage some fabrics or adhesives may not hold well. For special fabrics such as nylon, leather and Lycra spandex, different films are required. Ordinary canvas material can also be ironed, and the effect of ironing and pressing will vary depending on the material, and the actual situation shall prevail.

Precautions You Should Know

1. If the temperature of the T-shirt heat press machine is too high, the surface of the material will be burnt, and if the temperature is too low, the material will not be ironed.

2. A high temperature cloth should be placed on the material before ironing, and the PET cannot directly contact the temperature surface of the hot press.

3. The PET should be peeled off when the material is cooled or slightly cold to avoid the hot melt adhesive not being completely melted and attached.

4. The shelf life of conventional HTV is one to two years, and because the hot melt adhesive for the substrate is unstable, it is best to use it within one year.

![[Starter Kit] Auto Heat Press Machine 15" x 15" 110V + Starter Kit Bundle](http://www.htvront.com/cdn/shop/files/20240425-170634_385x.jpg?v=1714036345)

![[Premium Bundle] Auto Heat Press Machine 15" x 15" 110V + 20 rolls HTV Bundle 12“x3ft + Mini 2 Heat Press Machine + Random Sublimation & HTV Bundle ≥ $180](http://www.htvront.com/cdn/shop/files/1UK_4_22c12b1b-12dd-4105-ac25-93e2faae6a8c_385x.jpg?v=1713863580)