Order & Get Your Valentine’s Gift!

Order & Get Your Valentine’s Gift!

Recommended products

SECURED PAYMENT

FREE SHIPPING ON ORDERS $39+

3-15 Days Delivery

MONEY-BACK GUARANTEE

Your satisfaction is our priority

Order & Get Your Valentine’s Gift!

Order & Get Your Valentine’s Gift!

3-15 Days Delivery

Your satisfaction is our priority

Order & Get Your Valentine’s Gift!

Order & Get Your Valentine’s Gift!

|

|

|

Reading time for 12 min

Are you interested in trying your hand at DIY crafting, but don't know where to begin? Don't you worry- you've come to the right place!

This HTVRONT guide is poised to guide you in every step in preparing custom T-shirts, cool-looking stickers, and even beautiful cards. From choosing proper materials, such as HTV and adhesive vinyl, to perfecting a cutting machine and heat press, you will get well on your way to becoming a professional crafter.

We'll go over some of the basics, helpful tips, and introduce some cool tools along the way. Now, let's get creative and grab our vinyl!

A cutting machine is an all-around gadget that can cut various materials making it suitable for home uses. Here are some HTVRONT materials to use with the cutting machine and their detailed descriptions:

Adhesive vinyl

Printable Vinyl

Heat Transfer Vinyl

Adhesive vinyl are self-adhesive sheets that you can instantly apply to various surfaces.

HTVRONT stickers are mainly made from PVC material which is safe for use with a PET backing and liner to prevent damage. We provide both roll and sheet formats to meet diverse demands.

What's more, you need to understand what transfer tape is. This tape always comes along with adhesive vinyl. Transfer tape is used to apply an adhesive vinyl image off the vinyl release paper onto whatever surface it can be placed. Contact paper for vinyl transfer enables easier transferring of designs to projects.

Most adhesive vinyl will require some type of transfer film or tape. The transfer tape attaches itself to the release paper side of the vinyl for a moment and helps remove the release paper exposing the sticky side of the vinyl. It is useful for maintaining everything in position to assist in the moving of the entire design from the backing to the surface. After applying the vinyl, the transfer belt is to be removed.

Adhesive vinyl ensures effective prevention of damage to the back and loss of the adhesive film during cutting. It also possesses aggressive adhesion and excellent water resistance helps in well bonding to smooth surfaces and even using it outdoors does not peel the bond off.

For a deeper understanding of how adhesive vinyl works, you can refer to this helpful guide on permanent vinyl applications.

Plus, HTVRONT adhesive vinyl can be used indoors or outdoors but has an indoor maximum service period of 3 years and one year for outdoor use.

When using HTVRONT vinyl adhesive, please ensure you distinguish between the front and back during cutting to avoid damaging the PET layer. It’s also worth noting that uneven surfaces will affect the vinyl’s adhesion effect. Ensure you store the material in room temperature. Excessive cold or heat can affect the viscosity and thus affect the cutting effect.

To craft your design using adhesive vinyl, you’ll need these materials:

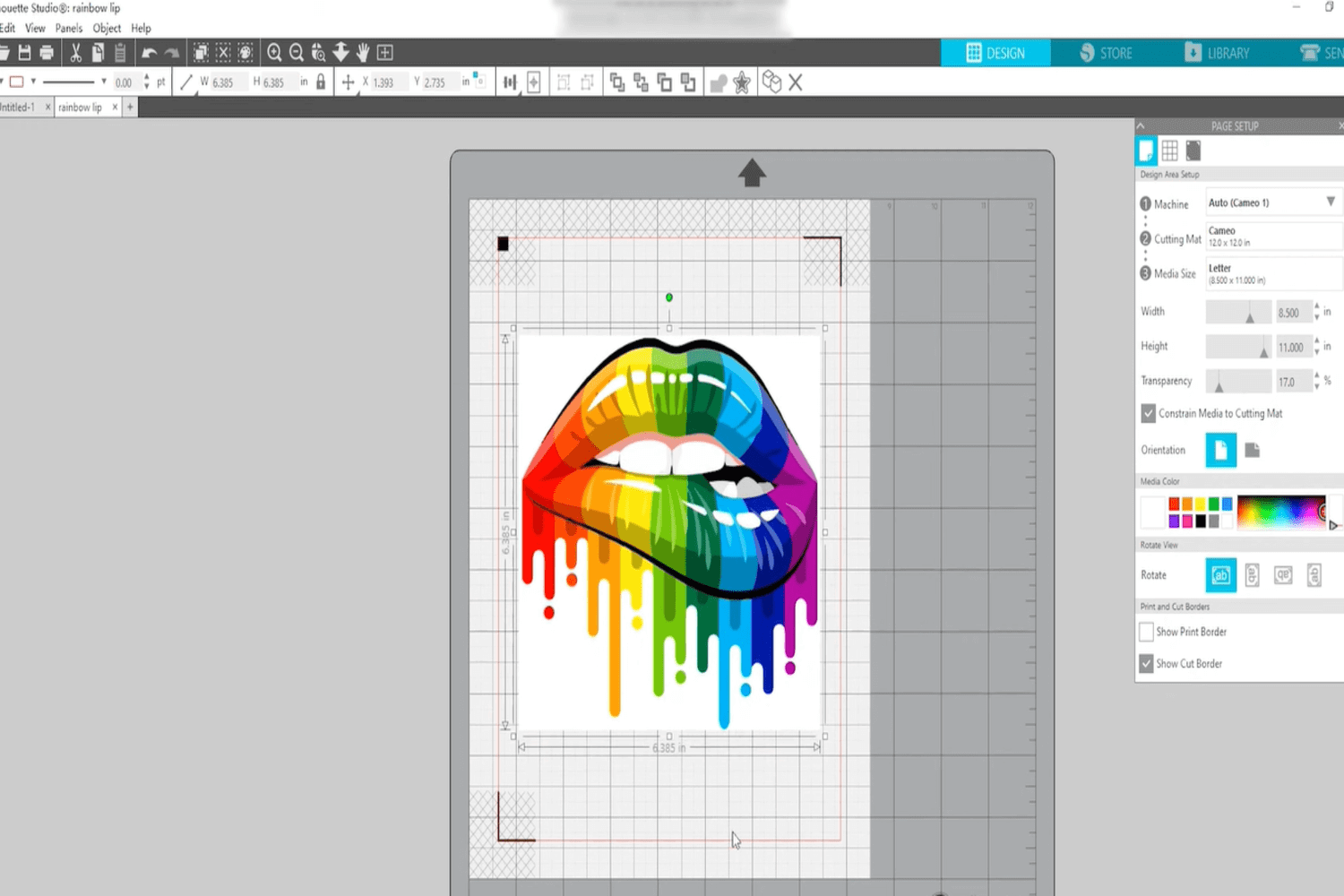

Cricut, Silhouette or Loklik machine

Adhesive vinyl

Weeding tool

Transfer tape

Squeegee or credit card

Clean surface for application

Step 1: Cut the Design

Use a Cricut or Silhouette to cut your design. Trim away excess vinyl for future use.

Step 2: Weed the Design

Peel away excess vinyl, starting from one corner. Use a weeding tool to remove small pieces, revealing the full design.

Step 3: Apply Transfer Tape

Place transfer tape over the design. Burnish with a squeegee or credit card to transfer the vinyl to the tape.

Step 4: Transfer the Design

Peel the transfer tape from the backing. Apply it to a clean surface, starting from the middle to avoid creases or bubbles.

Step 5: Finish the Project

Rub over the design to ensure it sticks. Carefully peel off the transfer tape.

And there you have it - a clean vinyl print that’s sure to last for years to come. On the other hand, if you’d like to remove your adhesive vinyl sooner, here’s an easy-to-follow video tutorial to guide you through it:

Printable vinyl (also known as printable stickers or printable vinyl sticker paper) is a versatile material that you can print with any design using a standard printer. Compared to normal sticky notes, printable vinyl can be produced in various colors and intricate patterns.

The thickness of our printable vinyl is neither too thin nor too thick therefore it can be used in the majority of printers and is less susceptible to tearing or getting stuck while printing. The HTVRONT printable vinyl has a one-year shelf life and a quick-drying feature that allows for rapid ink absorption.

Please print the design directly onto the adhesive side. Also, avoid applying to soft, dirty, or uneven surfaces. The product is waterproof but should not be submerged in water.

Use the "Other photo inkjet paper" setting in your printer for better results and water resistance. Note that different print modes may result in slight color variations. For complete waterproofing, consider laminating the printed material.

Here are the materials you’ll need to apply printable vinyl:

Cutting Stone

HTVRONT Printable Vinyl

Mug

Scraper

Scissors

Step 1: Print your Design

Insert your printable vinyl into your printer and use the recommended printing parameters to print your design. Leave it for about 2 minutes after printing.

Step 2: Cut Your Print

Use scissors to cut the printed vinyl according to your specifications.

Step 3: Laminate Your Print

HTVRONT printable vinyl includes laminated paper in its packaging. Take the laminated paper and cut it to fit the size of your design. Use the scraper to push out the air bubbles.

Step 4: Cut the Exterior Frame

Place the laminated print in the cutting stone and get rid of the exterior frame for a clean finish.

Step 5: Stick the Print to Your Object

Stick the clean-cut laminated vinyl to your object and use the scraper for a more permanent and bubble-free stick.

Step 6: Wash and Wipe the Finished Design

Wash the design and wipe it with a clean cloth to remove any fingerprint traces, and voila! A polished and beautiful vinyl design.

Heat Transfer Vinyl (HTV) is a composite material made up of a polyester film (PET), a film layer, and a hot melt adhesive backing. When heated, the hot melt adhesive melts, creating a bond that adheres the design firmly to various surfaces.

HTVs can be made from polyurethane (PU), thermoplastic polyurethane (TPU), and polyvinyl chloride (PVC) materials. HTVRONT specializes in PU HTV. Compared to PVC, PU is more environmentally friendly, heat resistant, flexible, and less prone to peeling. HTVRONT offers HTV in both roll and sheet formats.

Our high-quality heat transfer vinyl is easy to cut, weed and transfer. It is compatible with most cutting machines and measures 12" x 3ft which is suitable for beginners and creators. Our heat transfer vinyl is made of soft PU material, which is lighter and thinner.

Make it a point to always use a heat transfer sheet in between the material and the heat press in order to avoid any damages to your materials. Do not hastily remove the PET, in order to achieve the best results allow the material to cool only a tiny bit so as to ensure complete melting and bonding of the hot melt adhesive.

While the typical shelf life of HTV is between one and two years, it's advisable to use it within one year. This is due to the instability of the hot melt adhesive in the base material over time.

We have six different types of heat transfer vinyl: regular style, glitter style, puff style, flocked style, soft metal style, and chameleon style.

A heat press machine is a fundamental device that makes use of heat as well as pressure to transfer designs on different surfaces. HTVRONT provides various helpful heat presses like Auto Heat Press, Manual Heat Press & specific heaters such as Hat and T-shirt presses and mini models for smaller projects.

This section will explain these heat press machine printing material and printing technique:

Heat Transfer Paper

Sublimation

Heat transfer paper is specifically designed for 100% cotton or cotton/polyester blend fabrics. HTVRONT currently offers both dark and light-colored heat transfer paper. We exert the utmost care and attention to detail when developing our heat transfer paper. This includes using high-quality materials that are compatible with most inkjet printers to achieve excellent prints. It has a superb stretch and durability allowing multiple machine washing without fading, wrinkling, or peeling.

Heat transfer paper can be used on dark and light colored cotton fabrics. For optimal results, it is recommended for fabrics with a cotton content exceeding 60%. Its primary application is in the customization of textiles, including clothing and canvas bags.

Be cautious with low heat ironing, as it may cause color fading. After ironing, wait 48 hours before washing in cold water. The product is recommended for up to 30 cold water washes. Before wearing or storing, make sure to wash the item.

You will need the following supplies for your project.

HTVRONT Heat Transfer Paper (printable vinyl)

HTVRONT Auto Heat Press Machine

100% Cotton T-shirt

Step 1: Position Your Design

Position your printed design at the center of the cotton T-shirt. Adjust the heat press between 150 to 165 degrees Celsius or 302 to 329 degrees Fahrenheit.

Step 2: Place the Heat Transfer Paper Over the Design

When your design is well placed, take your heat transfer paper and place it over the design.

Step 3: Heat your Design

Allow the design to heat for 15 seconds. Avoid interfering with your press while it transfers your design.

Step 4: Admire the Finished Print

Once the 15 seconds are up, open the press to release the finished design. Wait for at least 10 to 20 seconds to allow it to cool, then take it out. You’ll notice that the design has a similar texture to heat transfer vinyl (HTV).

Sublimation is a printing process where dye-sublimation transfer ink is applied to paper or plastic film. Using heat and pressure, the printed image is transferred to fabric. During this process, the dye turns into gas and bonds with the fabric, creating a permanent, vibrant print.

Sublimation supplies are essential for creating vibrant, long-lasting prints on various items like mugs, T-shirts, and more. These supplies include:

Sublimation Ink: Specialized ink that turns into gas when heated, bonding with polyester or polymer-coated surfaces.

Sublimation Paper: A transfer medium that holds the sublimation ink until it's applied to the blank surface.

Sublimation Blanks: Items that are coated with a special polymer layer, such as T-shirts, mugs, and phone cases, allowing them to accept sublimation ink.

Heat Press Machine: Used to transfer the ink from the paper onto the blank using heat and pressure.

You’ll need these items for a successful sublimation process:

Heat Press

HTVRONT Sublimation Paper

T-shirt(cotton<30%)

Step 1: Place the Printed Sublimation Paper on T-Shirt

Having printed your design on the HTVRONT sublimation paper, position it at the center of your T-shirt and place it on the heat press for printing.

Tip: Medium to high pressure ensures a good transfer, but make sure it's not too high to avoid damaging the T-shirt.

Step 2: Heat the Design

Set your heat press to 180-200°C (356-392°F), then let it heat for 40 seconds.

Step 3: Peel the Paper

Once printed, peel out the sublimation paper to reveal the finished result.

Here’s an enhanced version of the "Sublimation on HTV" section that incorporates your additional details about the advantages of thermal sublimation lettering films:

Sublimation on Heat Transfer Vinyl (HTV) is an excellent method to apply detailed, colorful designs to cotton fabrics and dark-colored garments.

Normally, direct sublimation works only on light-colored polyester fabrics, and sublimation paper cannot be applied directly to cotton because the ink does not adhere well, resulting in poor-quality transfers.

Similarly, traditional heat transfer vinyl typically comes in single colors, limiting its design possibilities. By using sublimation HTV, or thermal sublimation lettering films, you can bypass these limitations and combine the vibrant, full-color designs of sublimation with the versatility of HTV.

Sublimation HTV is known for high color saturation, producing vivid and detailed designs, and excellent adhesion, which ensures durability even after multiple washes.

It is easy to weed and cut, making it ideal for intricate designs. After pressing, the protective film peels smoothly without causing wrinkles or blistering, ensuring a clean finish.

HTVRONT Sublimation HTV can be used on a wide range of cotton-based fabrics, including T-shirts, bags, pillows, and socks. This method allows you to apply colorful, durable designs onto fabrics that would otherwise be unsuitable for direct sublimation, such as cotton or dark materials.

Here’s what you’ll need to apply sublimation HTV:

Sublimation Compatible HTV

Sublimation Paper

Sublimation Ink Printer

Scissors

Cutting Mat

Cutting Plotter or a Craft cutter with a blade

Weeding Tools

Heat Press Machine

Teflon Sheet

Cotton T-Shirt

Step 1. Create Your Design

Edit the design you want using your desired image editing software. Extract the contours you’ll use for the cutting process.

Step 2. Print the Design

Print the image on sublimation paper using the sublimation printer. Ensure you match it with the sublimation ink. Mirror the design before printing to prevent reverse imaging on the T-shirt.

Step 3. Cut the Contours

Use the same software and a cutting plotter/craft cutter with a blade to cut out the contours on the sublimation HTV. Trace out the printed image using the machine’s ‘print-then-cut’ setting.

Step 4. Pre-heat the T-shirt/Garment

Ensure the heat press is set to 380-400℉ (180°C and 200°C). Take your T-shirt and spread it on the heat press.

Step 5. Apply the Heat Press

Set the heat press to the desired temperature then place the HTV Vinyl on the T-shirt and heat press it for approximately 5 to 15 seconds. Allow it to cool, and then peel off the carrier. Heat-press your design on top of it once the sublimation medium is set.

Carefully align the printed sublimation paper on top of the HTV Vinyl. Set the heat press temperatures to 380-400℉ and heat press it on the T-shirt for 40-60 seconds. Once it cools, take off the carrier.

Here’s a quick summary of all the printing options covered in this article:

Material |

Description |

Color Capabilities |

Component |

Adhesive vinyl |

A common type of self-adhesive note that can be customized with various graphics. |

Single pattern, unable to meet multi-color requirements. |

Film component |

Printable vinyl |

Printable stickers are adhesive labels that can be printed on and attached to various surfaces, except fabrics. |

Full-color printing |

Film component |

Heat transfer vinyl |

Modifying the properties of the adhesive. |

Single-color designs, offering a narrow color palette. |

Film component |

Heat transfer paper |

Heat transfer: Custom patterns and colors are achieved through printing. |

Full-color printing |

Film component |

Sublimation |

Designs are printed directly onto the fabric using a specialized printer, where the ink is embedded into the fabric fibers. |

Full-color designs |

Film-free component |

Sublimation HTV |

DIY on pure cotton fabrics. |

Full-color designs |

Film component + Film-free component |

1. What’s the difference between heat transfer paper and heat transfer vinyl?

Heat transfer paper allows you to transfer printed designs onto fabric, making it great for complex images like photos. Heat transfer vinyl (HTV) is a solid-colored material that’s cut into shapes or letters, perfect for bold, simple designs. HTV requires a cutting machine, while heat transfer paper can be used with a regular printer.

2. Can I use HTVRONT’s machines with non-HTVRONT materials?

Yes, HTVRONT machines can be used with non-HTVRONT materials. However, for the best results, it’s recommended to use HTVRONT’s own products, as they are specifically designed to work seamlessly with their machines.

3. What’s the best way to care for my heat-transferred items?

To care for heat-transferred items, wash them inside out in cold water and use a mild detergent. Avoid bleach and fabric softeners. For drying, tumble dry on low heat or hang to dry. This helps maintain the design’s durability and color vibrancy.

4. Can sublimation be used on dark fabrics?

No, sublimation works best on light-colored fabrics, especially those with high polyester content. For dark fabrics, you can use heat transfer paper or heat transfer vinyl to achieve vibrant results.

With the knowledge you’ve gained from this guide, you’re ready to dive into crafting custom T-shirts, eye-catching stickers, and beautiful cards. Our products are designed with quality in mind, ensuring you achieve the best results every time. HTVRONT’s materials and equipment will make your projects easier and more fun.

Reselect your machine

Reselect your machine

Reselect your machine

Reselect your machine

Reselect your machine

To improve our service quality, we value your shopping experience at HTVRONT official website and your willingness to recommend us to others. Please take a few moments to complete this survey.Your opinions are important to us. Thank you for your participation and support!

Website interaction (e.g., shopping page, promotion, order, payment process)

Product (e.g., product quality, style)

Logistics (e.g., shipping, delivery)

Customer Service (e.g., response speed, professionalism)

[Website - Shopping Page]

[Website - Promotion]

[Website - Order and Payment Process]

[Product]

[Logistics]

[Customer Service]